UTILIZE

Three Benefits of Utilization

1〈Branding〉Co-creating a brand with consumers

Give resources back to the community where they were generated. This kind of “local resources for local use”-based approach can lead to co-creation of a brand. The whole process contributes to establishing a deep relationship with local residents.Example: PET bottles collected by local residents can be turned into the uniforms of a local sports team.

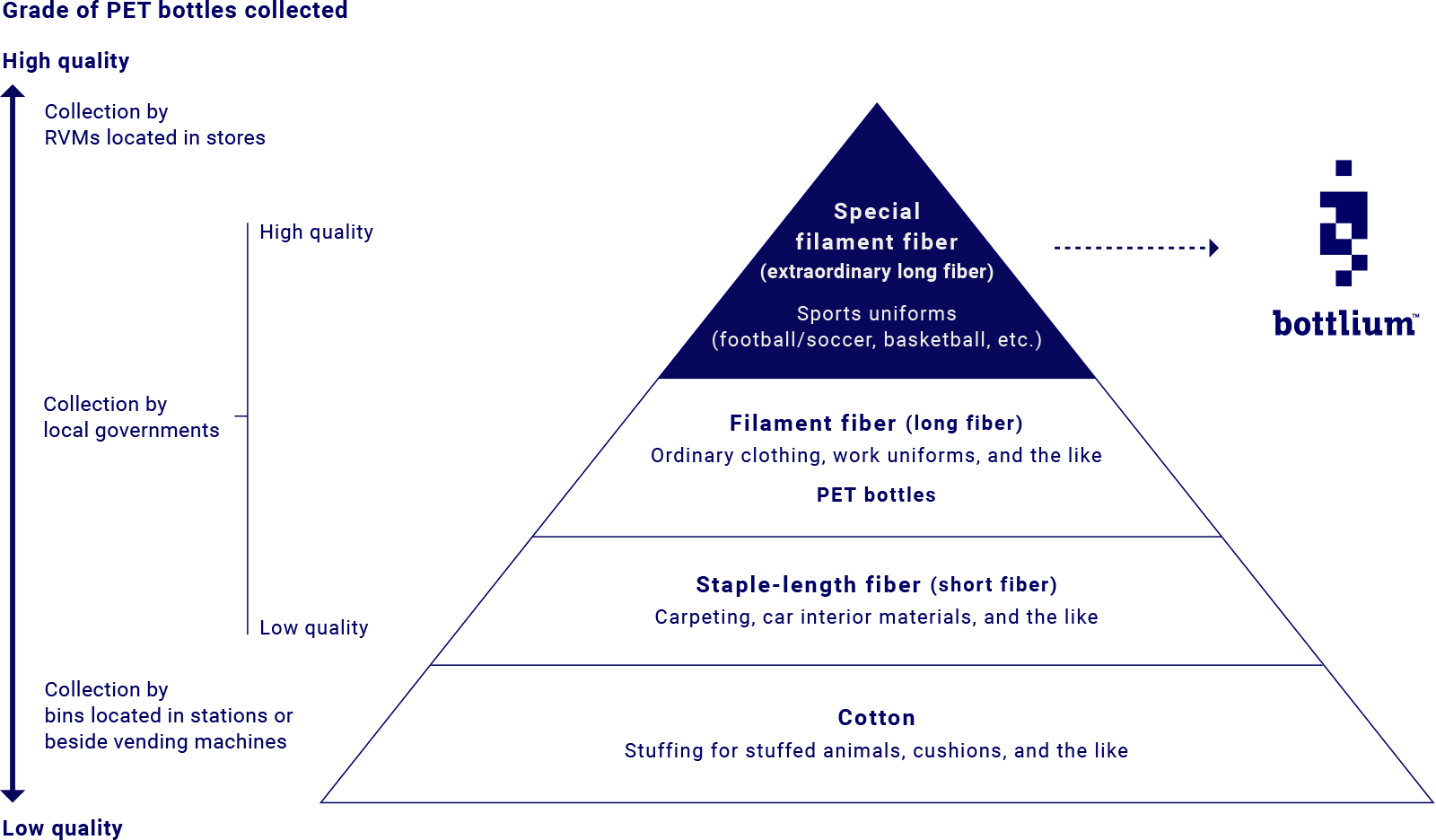

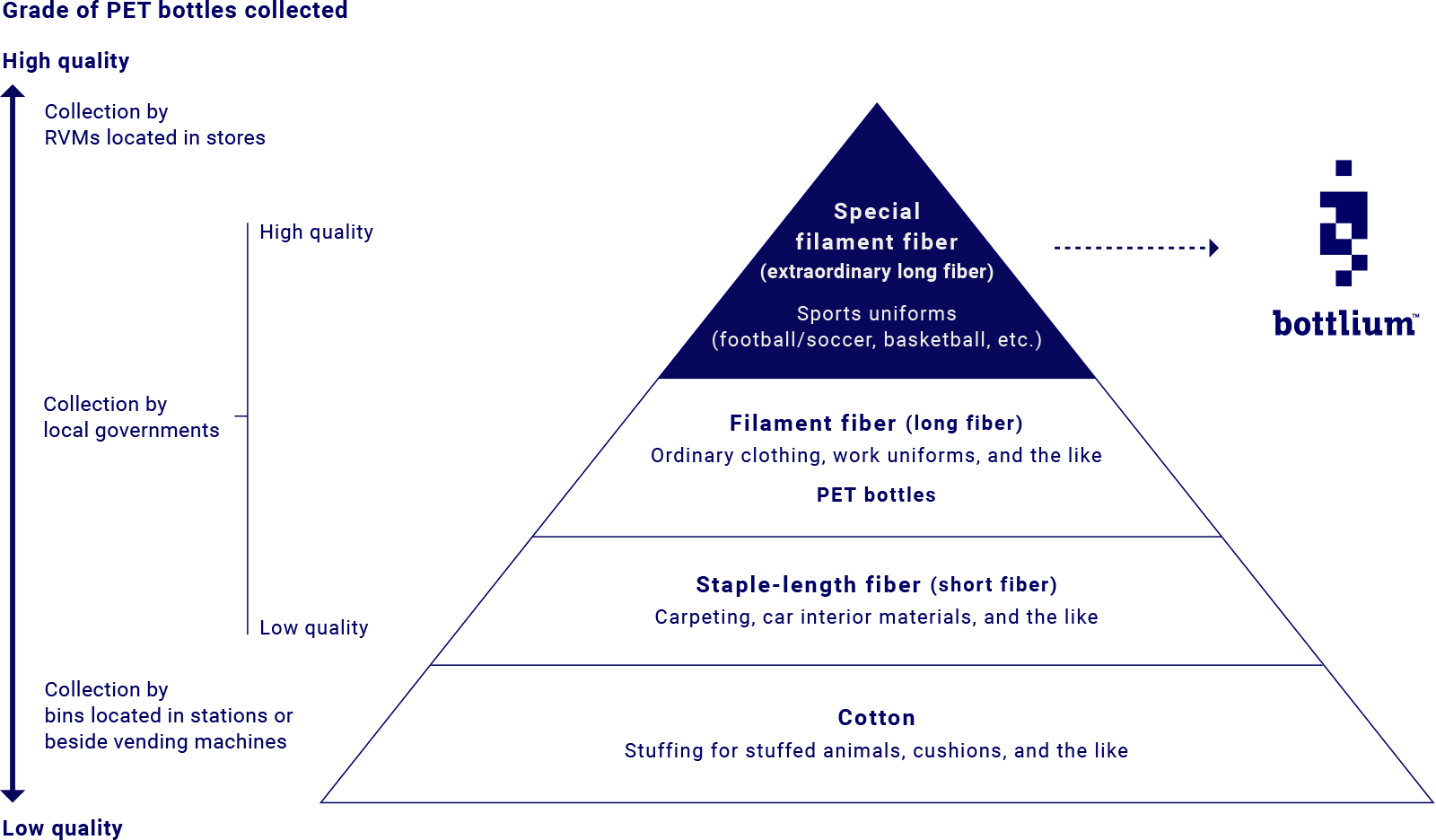

2〈Material for Products〉The highest quality* expands the possibilities for various applications

Among PET pellets made from collected PET bottles, bottlium® stands out as a special filament fiber, which is an extraordinary long fiber, with the highest level of quality and offers high functionality appropriate for processing into various products.

and more

and more

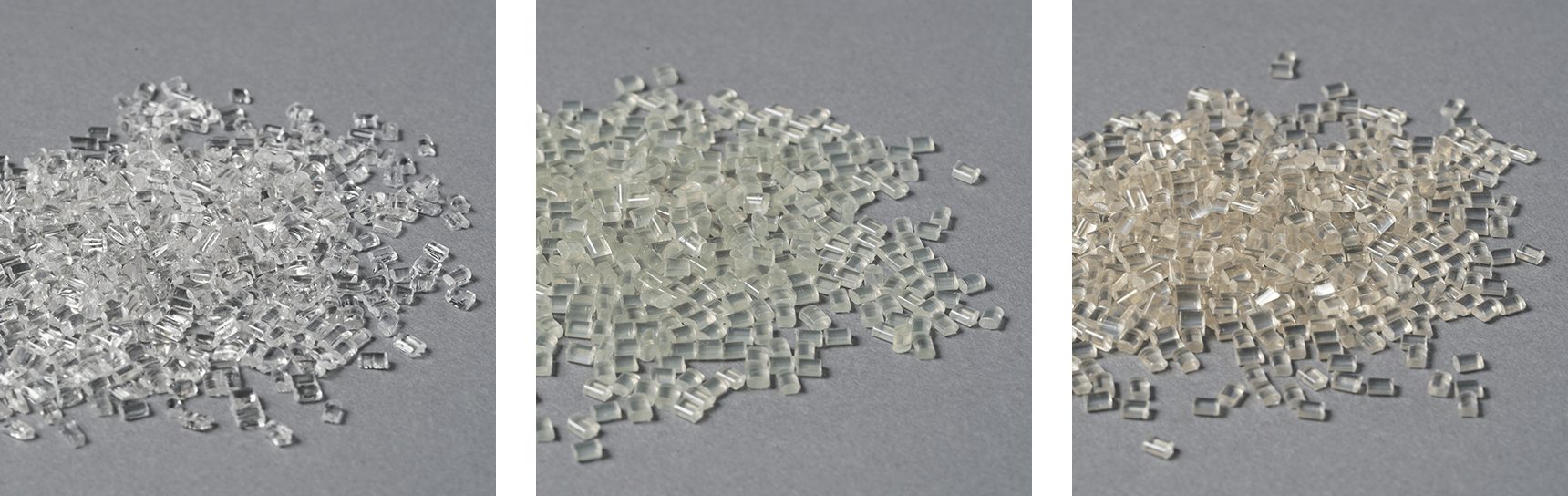

【The Grade of Special Filament Fiber】

Top-ranked quality among PET pellets made from collected PET bottles

Click here to enlarge the image.

Click here to enlarge the image.

Good quality comes from a good resource

Japan has avoided domestic production of colored PET bottles and therefore is in a unique position in the world in having only clear, high-quality PET bottles as a recyclable resource. However, in many collection operations, PET bottles are mixed with trash and/or contain unconsumed liquids, which makes it difficult to recycle them.

bottlium® is 100% made from PET bottles that have been carefully washed and sorted by consumers and is versatile thanks to the transparency and coloring friendliness unique to Japanese PET pellets.

↑bottlium®

↑bottlium®

3〈Sustainability〉Thorough pursuit of sustainability

Going beyond reusing PET bottles as

a resource, we have also given the utmost consideration to the environment in building our collection and production processes. We as

a company continue to demonstrate

a wholehearted commitment to the realization of a sustainable environment.

Clean water quality enables repeated use of washing water

Using eco-friendly aqueous cleaning, our production process discharges wastewater that is low in pollutants. The environmental burden imposed by our wastewater treatment is the lowest among comparable PET pellet producers*.

*Surveyed recyclers handling 10,000+ tons/year

(Our survey; as of April, 2021)

Reducing carbon dioxide emissions to the lowest possible level in every process

Compressing PET bottles down to one-third their size inside RVMs leads to as much as a 38.2% reduction in carbon dioxide emissions* during transportation from collection point to production facility. We also seek to utilize resources efficiently during our PET pellet production process. Our efforts to curb carbon dioxide emissions cover the entire process from collection to production.*In comparison with collection operations by local governments